Transform your supply chains like never before with our cutting-edge management system designed to boost your business efficiency. Seamlessly integrate various processes, from procurement to order fulfilment, effortlessly obtaining a complete view of your operations. Our intuitive software empowers you to pinpoint bottlenecks, analyse performance metrics, and proactively enhance productivity. Revolutionize your supply chain management to reduce costs, optimize profitability, and surpass customer expectations. Elevate the overall effectiveness of your organization's supply chain logistics while maintaining resilience and productivity. Moreover, streamline contract compliance by automating workflow procedures, even with external suppliers, to foster a unified perspective in a dispersed setting. Simplified supply chain management methods provide invaluable insights, control, and visibility into processes, ultimately elevating the customer experience.

Real-Time Updates

Supply chain management uses real-time updates to record and keep track of production data, financial reports, inventory, and outstanding orders. This ensures that procurement, planning, and production systems all operate based on identical data.

Enhance Profitability

Achieve cost reduction in supply chain processes by efficiently determining the required timing for goods and materials to meet customer demand. Optimize production planning to minimize inventory levels while ensuring efficient order fulfilment.

Optimize Inventory

Improve inventory management through the comprehensive assessment of available stock across multiple locations. This enables businesses to optimize stock utilization while minimizing overall inventory levels, resulting in reduced overhead expenses and carrying costs.

Unified

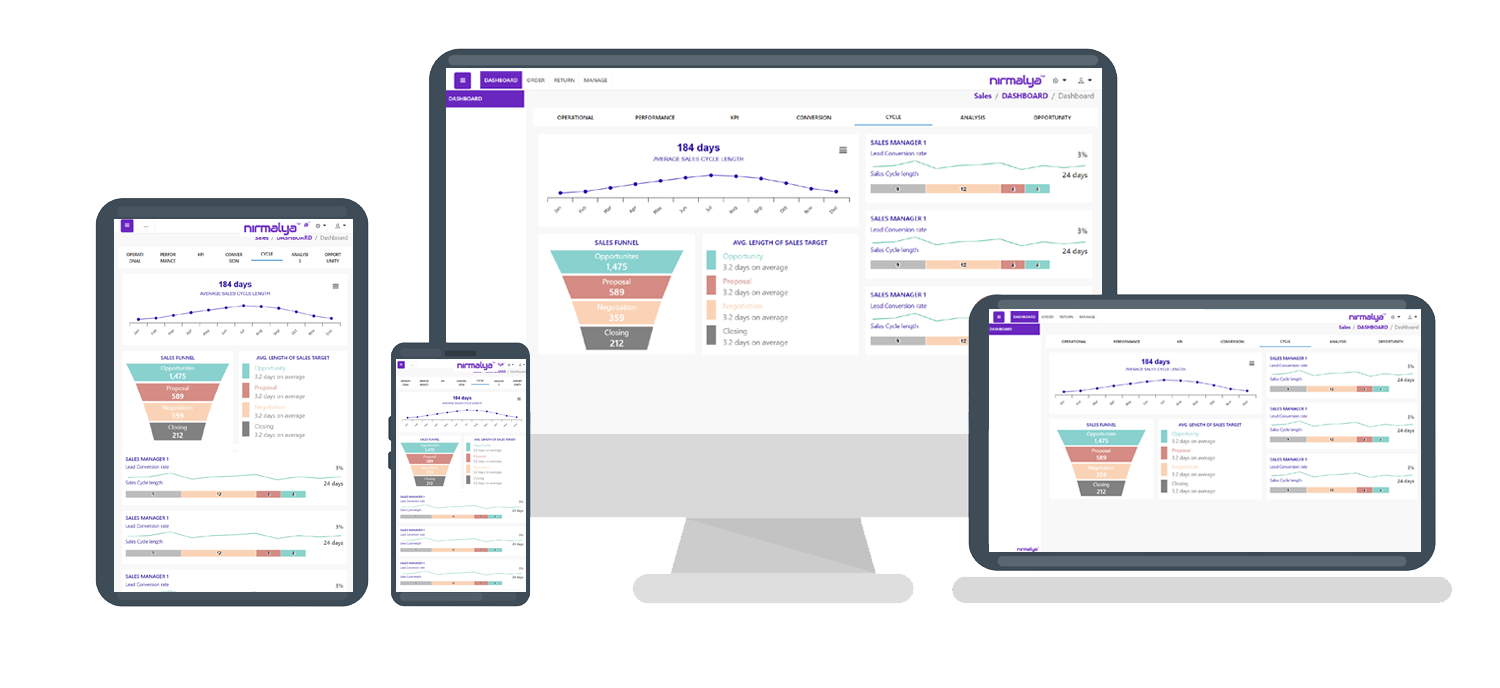

Bringing data, technology & expertise together to transform your business and make future-ready.

Connected

Integrating different varieties of data to enhance transparency, insights, and transform digitally to capitalize on data and innovate without boundaries.

Interoperable

Reliable & Resilient – your platform & partner for digital transformation without limits.

.jpg)

.jpg)