Enterprise Resource Planning

Improve business processes, enhance transparency, and effectively allocate time and resources to embrace change, encourage innovation, adapt to evolving industry trends, promote innovation, and stay ahead of the competition.

Customer Relationship Management

Establish a cohesive view of your potential customers, clients, partners, and vendors, giving sales, marketing, and support teams the ability to access current information to deliver exceptional customer experiences and drive sales growth.

Human Capital Management

Improve decision-making processes, customize employee experiences, and establish flexible workflows to support growth and adapt to different locations, fostering business expansion and meeting specific local requirements.

Supply Chain Management

Enhance business agility by responding quickly to market demands and facilitating efficient planning and execution of materials and goods movement in supply chain networks for sustainable growth in a changing market.

Smart Warehouse Management

Improve warehouse operations to efficiently handle the demands of the current market by effectively overseeing intricate fulfillment processes and achieving full visibility of inventory throughout the distribution center and store shelves.

Enterprise Asset Management

Enhance productivity, strategically schedule breaks, optimize asset performance, and minimize operational disruptions by effectively using web and mobile applications to increase asset value regardless of location or time.

We bring disruptive, innovative technology and solutions to market with greater efficiency and speed.

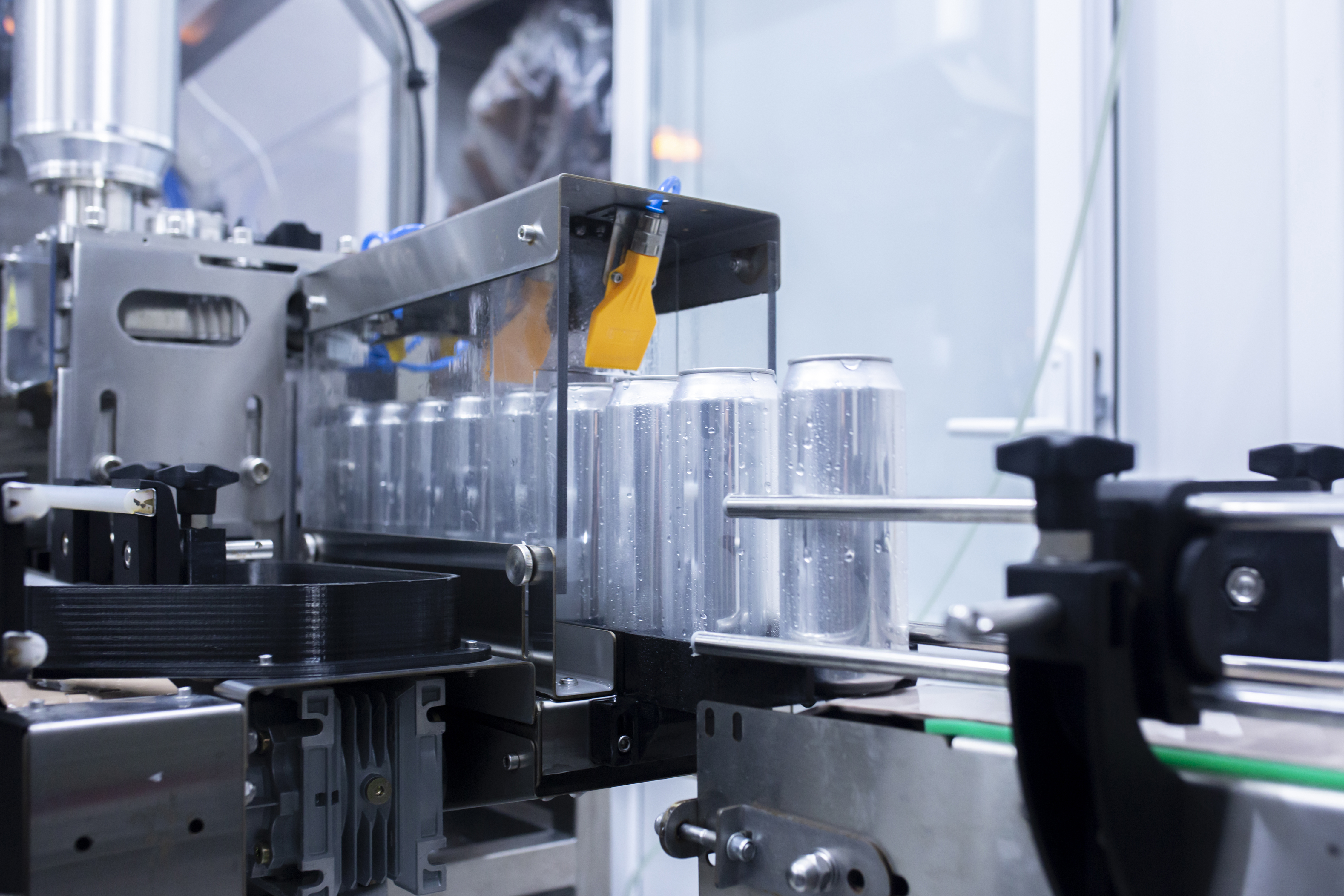

Manufacturing

Enhance operational efficiency by improving processes and tasks to maximize output, minimize wasted resources, gain valuable insights, and data-driven knowledge for informed decision-making and strategic planning.

Finance and Banking

Harness advanced business intelligence tools and strategies to drive innovation, enhance customer satisfaction, and optimize profits for all stakeholders, leveraging predictive and intelligent capabilities.

Building Materials

Address supply and demand challenges in a timely manner, while leveraging an integrated platform for construction materials to drive innovation and sustainability for the future.

Food and Beverage

Elevate customer engagement, discover cutting-edge transaction techniques, and broaden your reach in the food and beverage industry to cultivate strong customer relationships.

Healthcare

Enhance operational efficiency by optimizing processes and procedures, anticipate outcomes through strategic planning, and cultivate a culture of continuous improvement within the organization.

Hotels and Hospitality

Automate the process of establishing connections among your customers' engagements using advanced customer service solutions equipped with predictive and intelligent capabilities.

Whessoe Paves the Way with Unified Nirmalya Enterprise Resource Planning

Whessoe, a renowned sustainable readymix concrete manufacturer in Loas, has s

Orifood Transformed Operations with Real-time Analytics & Achieved Dominance in the Packaged Food Industry

Orifood, a prominent leader in food manufacturing and distribution in India,

.jpg)

Oriclean Revolutionized their Processes with Nirmalya Enterprise Resource Planning

As a prominent Detergents and Toiletries market leader in India, Oriclean rec